Introduction

Oil-free piston compressors have become increasingly popular due to their ability to deliver clean, oil-free compressed air, making them ideal for numerous industries. These compressors operate without the use of lubrication oil in the compression chamber, ensuring that the air produced is free from contaminants. In this blog post, we will delve into the specifics of oil-free piston compressors, discussing their design, operational mechanics, and the many advantages they offer. Whether for applications in food processing, pharmaceuticals, or electronics manufacturing, the benefits of using oil-free compressed air systems are significant and varied.

Defining Oil-Free Piston Compressors

An oil-free piston compressor is an air compressor that operates without oil for lubrication. Unlike traditional compressors that use oil, potentially contaminating the air, oil-free models use advanced technology to ensure clean compressed air.

The Mechanics of Oil-Free Piston Compressors

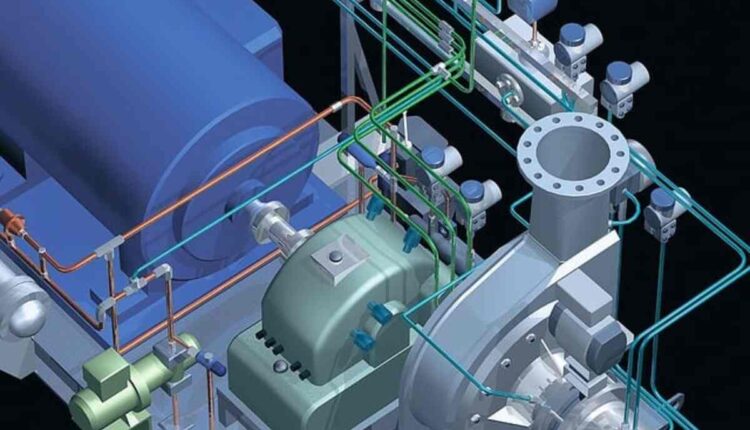

Oil-free piston compressors are engineered with innovative design features that facilitate efficient operation without the use of oil. These compressors often incorporate advanced materials, such as PTFE (polytetrafluoroethylene), which is renowned for its low-friction properties, on both the piston and cylinder walls. This strategic choice minimizes friction and enhances performance.

To further reduce reliance on lubrication, self-lubricating piston rings made from durable materials like carbon or nylon are employed. These rings are designed to withstand high pressures while minimizing wear and tear. In some advanced designs, mechanical contact is eliminated to eradicate the need for lubrication, while alternative materials, such as water or Teflon, are utilized to safeguard critical components from wear and heat.

Additionally, oil-free piston compressors are often equipped with intercoolers, which play a vital role in managing air temperature. Since there is no oil to provide inherent cooling, these intercoolers ensure that the air remains at optimal temperatures, thus enhancing the overall efficiency and longevity of the compressor. By integrating these sophisticated features, oil-free piston compressors deliver reliable performance and sustainability in various applications.

Key Advantages of Oil-Free Piston Compressors

- Clean and Oil-Free Air: These compressors produce contaminant-free air, suitable for food processing, electronics manufacturing, pharmaceutical production, and sensitive lab environments.

- Enhanced Efficiency and Performance: Designed for optimal performance, they eliminate airflow contamination and oil degradation, providing consistent compressed air output.

- Lower Maintenance and Operating Costs: The absence of oil reduces the need for oil changes and filter replacements, cutting down on maintenance time and costs.

- Environmental Friendliness: Oil-free operation prevents oil discharge into the atmosphere and often incorporates energy-efficient designs to reduce the carbon footprint.

- Versatility and Adaptability: Available in various sizes, oil-free piston compressors suit diverse applications, from dental clinics to automotive workshops.

Conclusion

Oil-free piston compressors have transformed the landscape of air compression by delivering pristine, oil-free compressed air suitable for a wide array of applications. These compressors stand out as a dependable and efficient choice for industries that demand contaminant-free air thanks to their numerous advantages. They offer enhanced efficiency, which translates to superior performance and energy savings. Additionally, their lower maintenance costs make them a cost-effective option in the long run. Environmentally conscious, these compressors contribute to a greener future by eliminating the need for oil, thus reducing potential environmental hazards. Moreover, their versatility allows them to adapt seamlessly to various operational needs, making them an ideal solution for diverse industrial applications.

Read also: Affordable Electric Scooters Available in Down under.